Comparative Analysis of Horticultural Lighting Systems

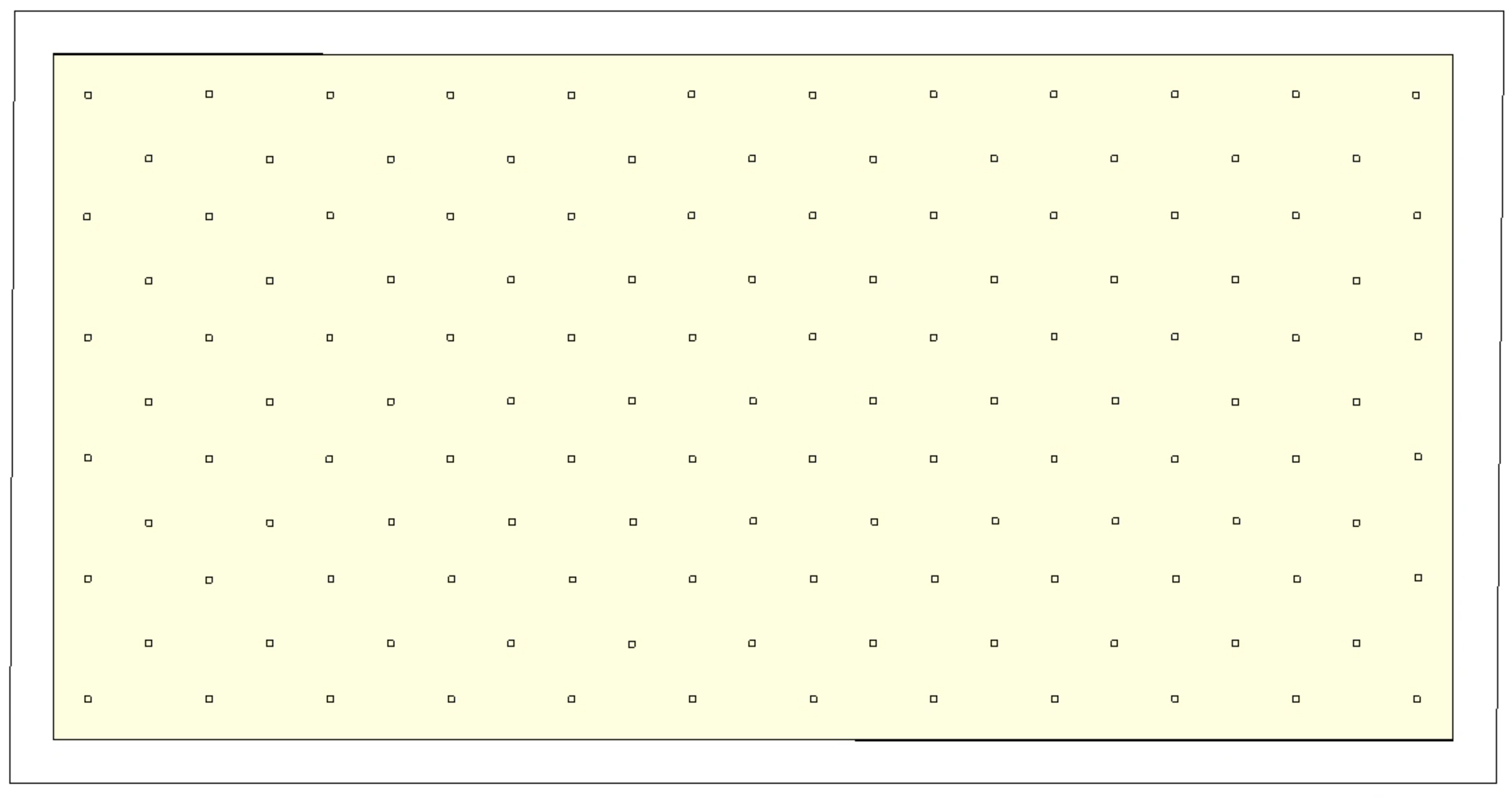

Centered-Square COB LED System

COB LEDs (Samsung BXRE-30E6500-C-83) are arranged in a centered square number sequence. No secondary optics are used. Layout is defined by the centered square number integer sequence (Online Encyclopedia of Integer Sequences: A001844):

\(C(n) = (2n-1)^2\)

Figure 1: Centered Square COB LED Arrangement.

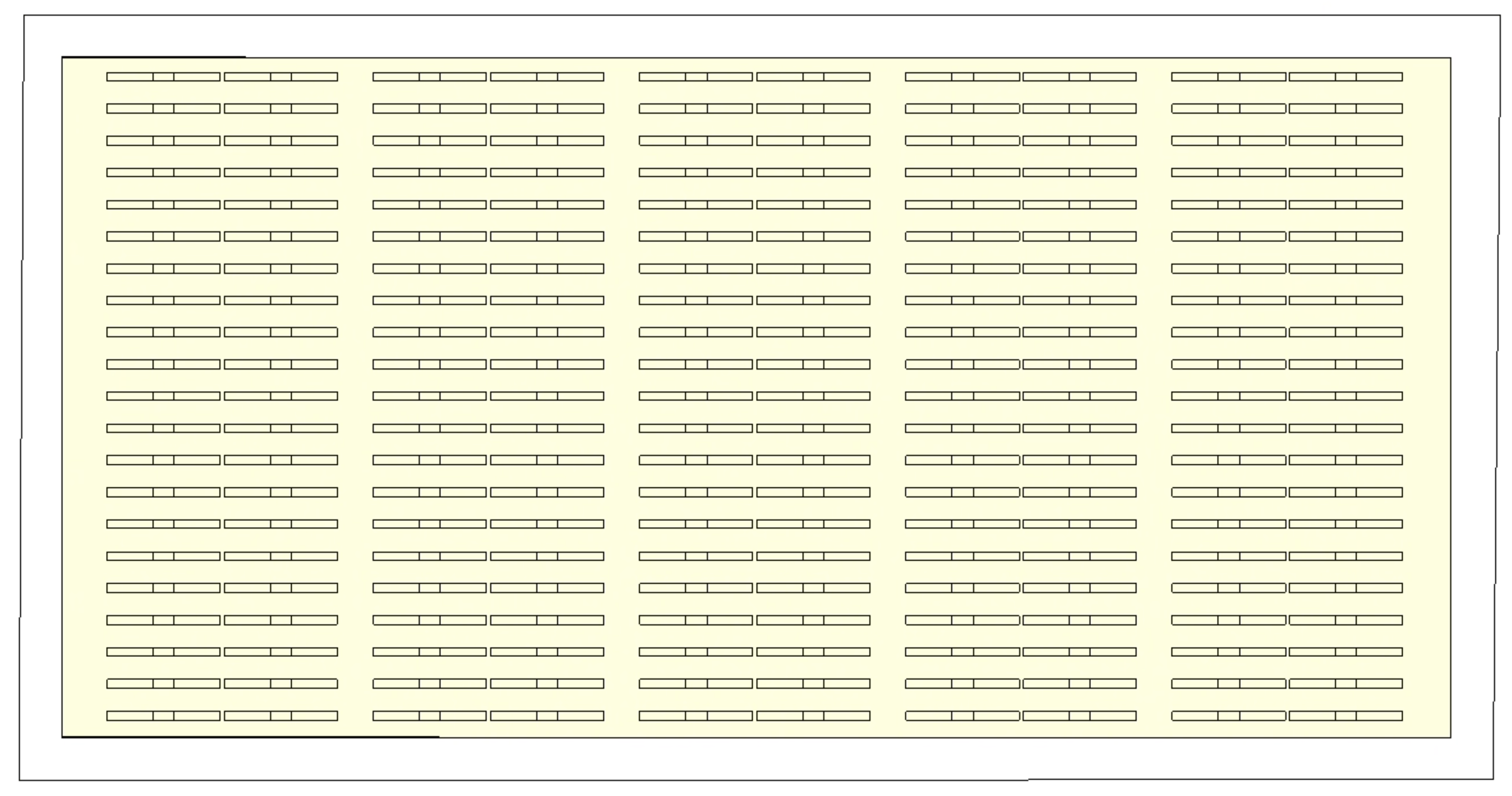

Uniform-Matrix Gen 2 System

Samsung SI-B8T502560WW modules are placed in a standard rectangular matrix layout, commonly used in commercial applications.

Figure 2: Uniform Matrix Arrangement of Gen 2 Modules.

Simulation Approach

Photometric data (.ies files), geometric arrangements, and surface reflectances were used in DIALux to simulate lux distributions. Results were then converted to PPFD using Spectral Power Distribution (SPD)-derived conversion factors.

Lux to PPFD Conversion

The conversion from illuminance (lux) to photosynthetic photon flux density (PPFD, in μmol m−2 s−1) uses the LED’s normalized spectral power distribution I(λ) over a wavelength range [λ1, λ2]. In our approach, PPFD is calculated as:

where:

- h is Planck’s constant,

- c is the speed of light,

- NA is Avogadro’s number,

- the factor

106converts moles to micromoles, - and the λ×10−9 term converts nanometers to meters.

Illuminance, E (in lux), is given by:

where V(λ) is the CIE photopic luminous efficiency function and 683 lux W−1 is the maximum luminous efficacy of radiation.

Therefore, the lux-to-PPFD conversion factor, C (in μmol m−2 s−1 lux−1), is:

Conversion factors used:

- Samsung Gen 2: 0.0179 μmol m−2 s−1 lux−1

- Samsung COB: 0.0138 μmol m−2 s−1 lux−1

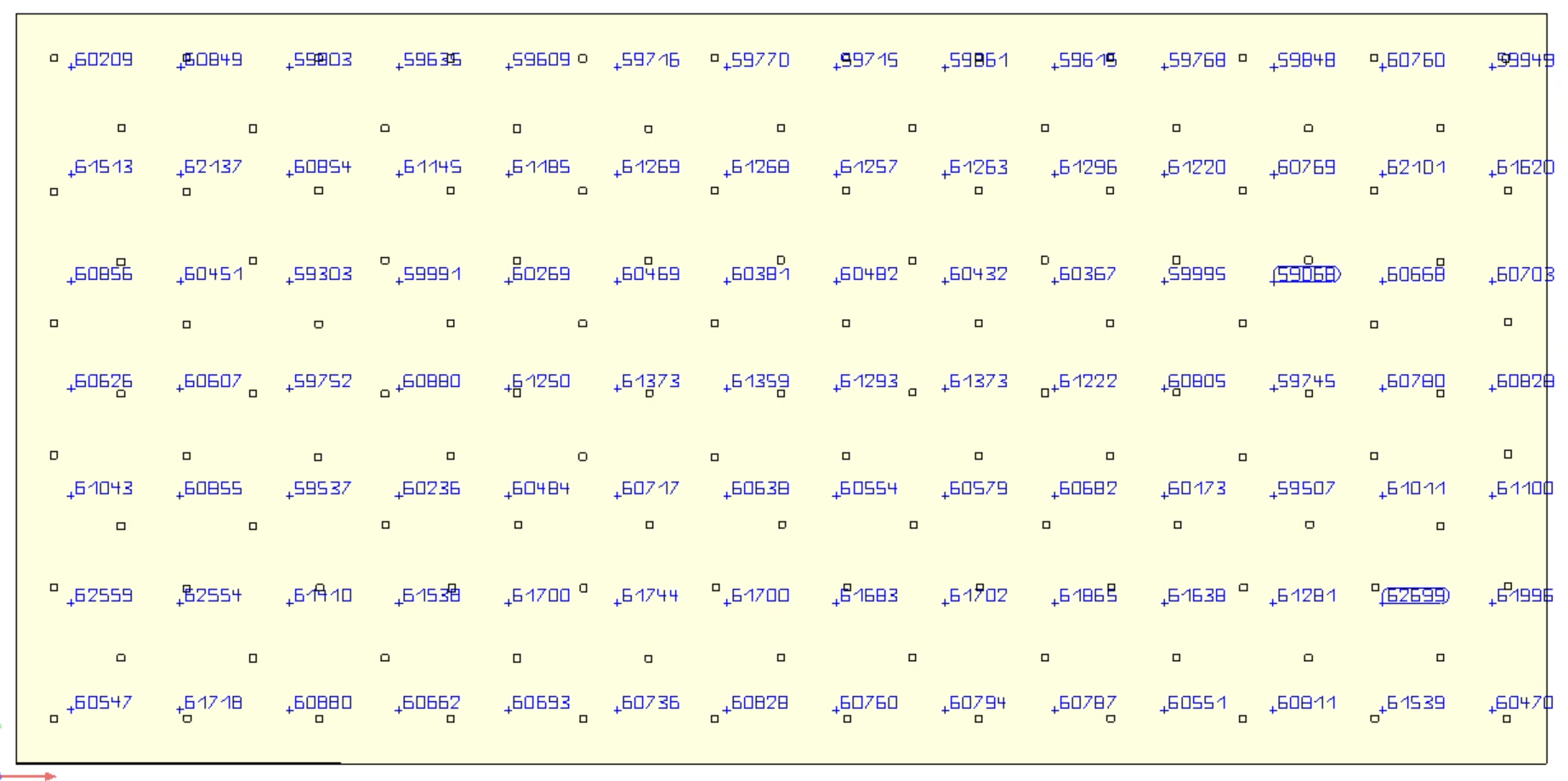

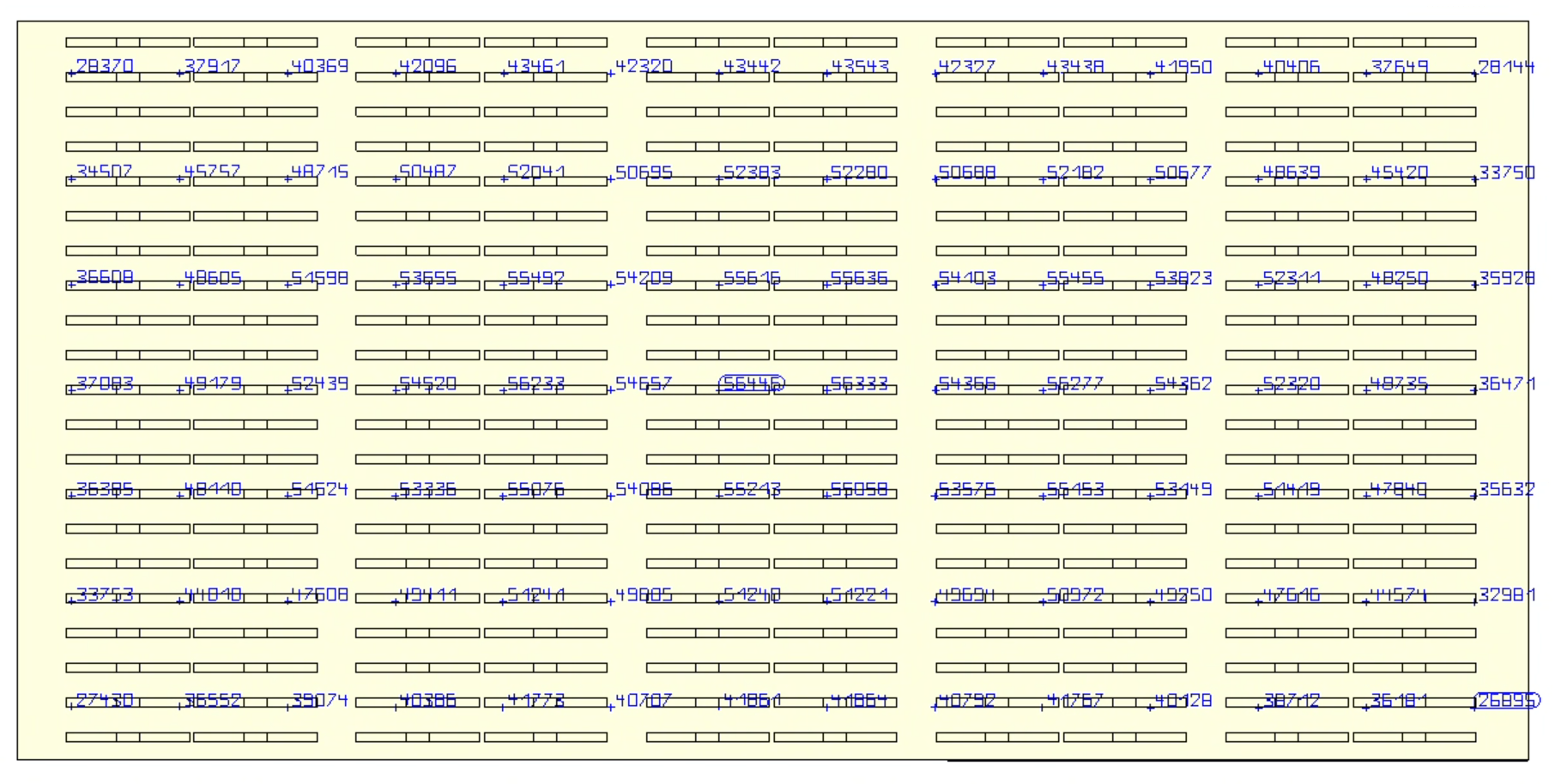

Results

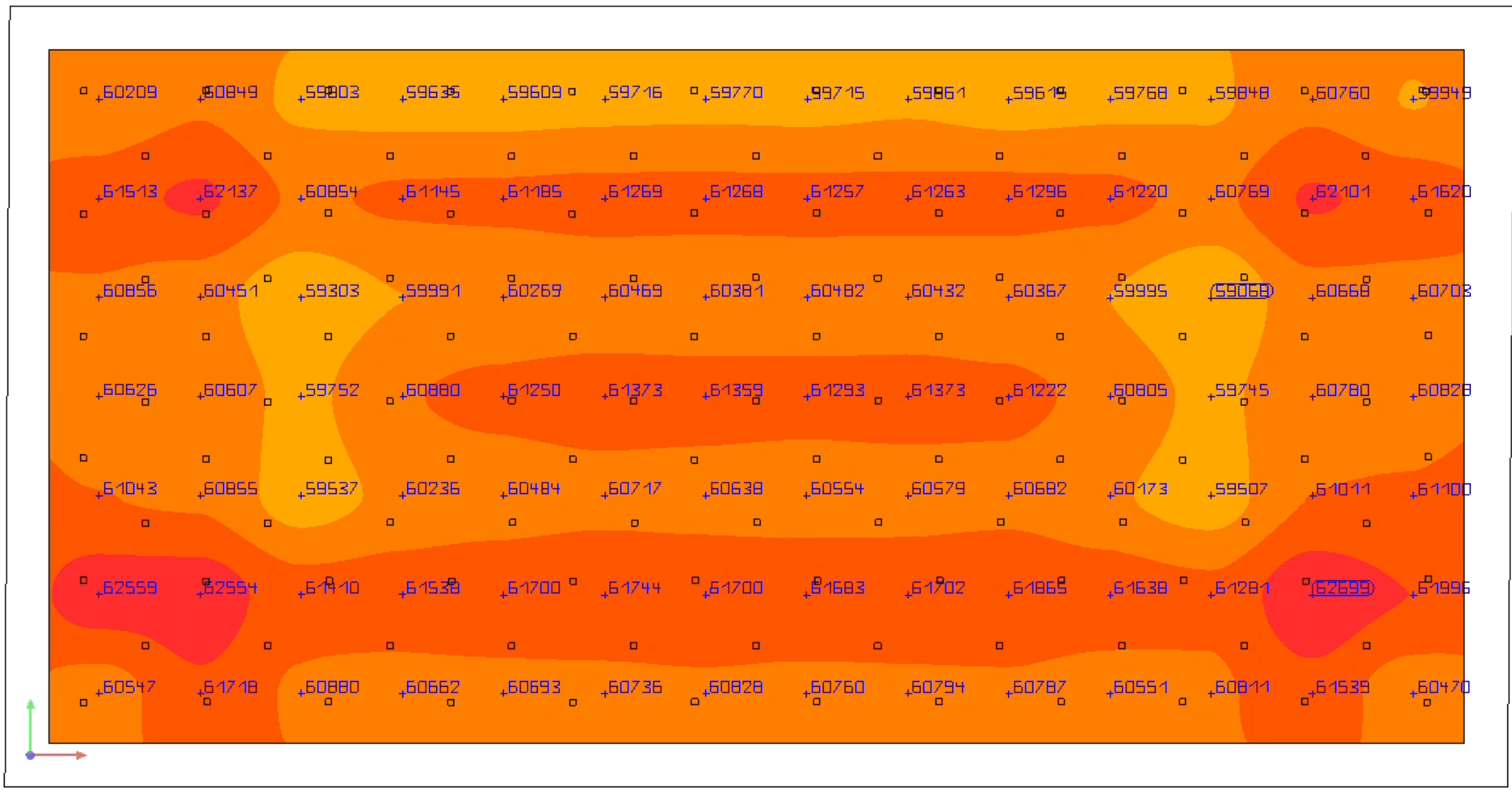

Figure 3: Novel System PAR Map

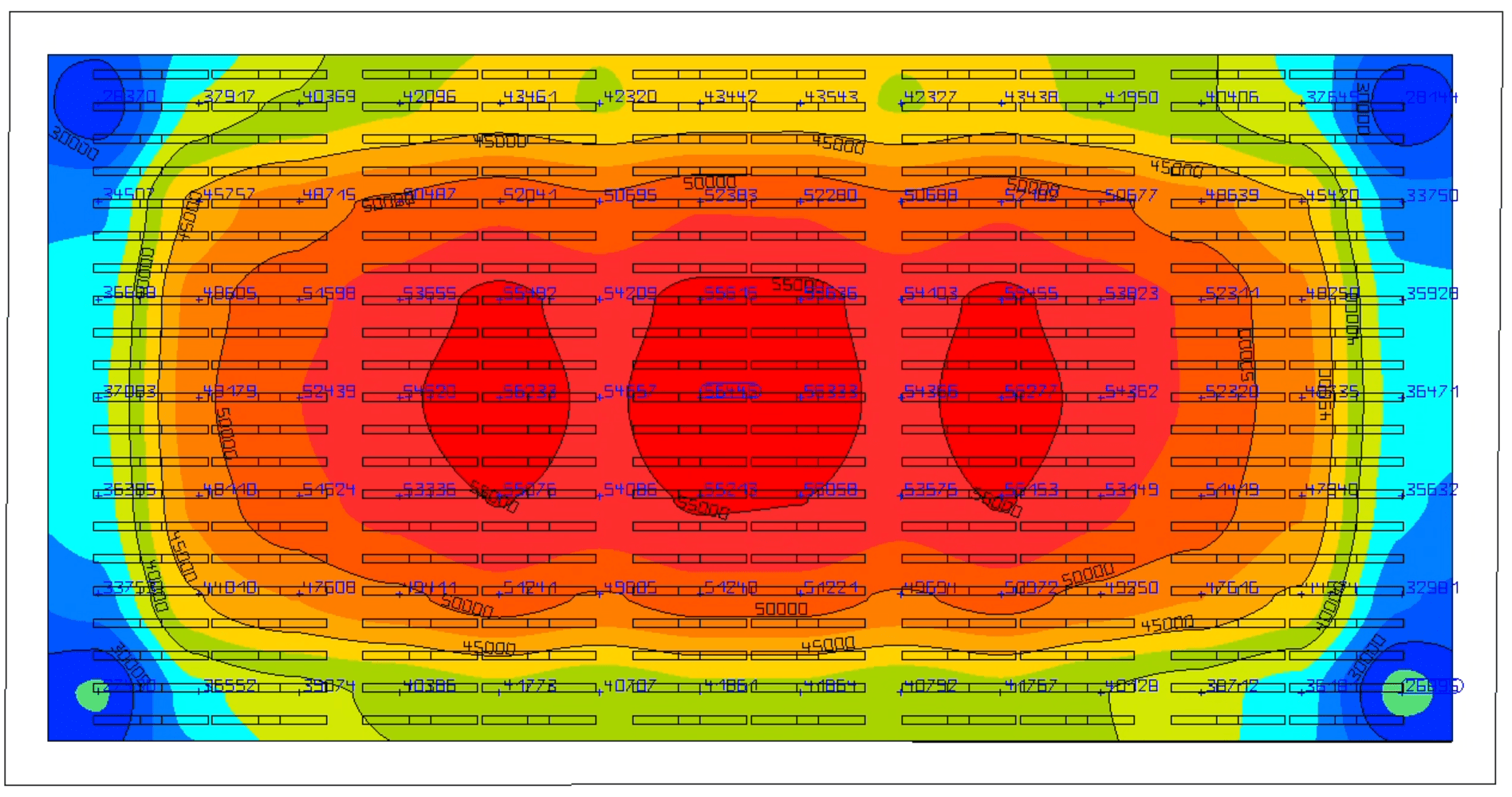

Figure 4: Conventional System PAR Map

Figure 5: Novel System Heatmap

Figure 6: Conventional System Heatmap

| Metric | Novel System | Conventional System |

|---|---|---|

| Average PPFD | 838.98 | 830.55 |

| RMSE | 10.28 | 138.10 |

| DOU (%) | 98.77 | 83.37 |

| MAD | 7.99 | 119.40 |

| CV (%) | 1.23 | 16.63 |

| Min/Max PPFD | 0.94 | 0.48 |

Mathematical Representation of Metrics

Here, we define the mathematical formulations used to calculate the metrics presented in the table above. Let Pi represent the PPFD value at the i-th measurement point, and let n be the total number of measurement points (here, n = 98).

-

Average PPFD (PPFDavg):

\[ \text{PPFD}_{\text{avg}} \;=\; \frac{1}{n} \sum_{i=1}^{n} P_i \]

-

Root Mean Squared Error (RMSE):

\[ \text{RMSE} \;=\; \sqrt{\frac{1}{n} \sum_{i=1}^{n} \bigl(P_i - \text{PPFD}_{\text{avg}}\bigr)^2} \]

-

Degree of Uniformity (DOU):

\[ \text{DOU} \;=\; 100 \times \Bigl(1 - \frac{\text{RMSE}}{\text{PPFD}_{\text{avg}}}\Bigr) \]

-

Mean Absolute Deviation (MAD):

\[ \text{MAD} \;=\; \frac{1}{n} \sum_{i=1}^{n} \bigl|P_i - \text{PPFD}_{\text{avg}}\bigr| \]

-

Coefficient of Variation (CV):

CV is the ratio of the standard deviation (σ) to the average PPFD, expressed as a percentage. The standard deviation is:

\[ \sigma \;=\; \sqrt{\frac{1}{n} \sum_{i=1}^{n} \bigl(P_i - \text{PPFD}_{\text{avg}}\bigr)^2} \]Thus

\[ \text{CV} \;=\; 100 \times \frac{\sigma}{\text{PPFD}_{\text{avg}}} \]Note: Since we use all data points, population and sample standard deviations coincide.