Commercial-Grade Functional Prototype

In partnership with Advanced Electronics Manufacturing (AEM), we successfully produced commercial-grade functional prototypes for our first patented system, a fixed-frame Chip-On-Board (COB) horticultural lighting array. Functional prototypes for our modularized system are in the works!

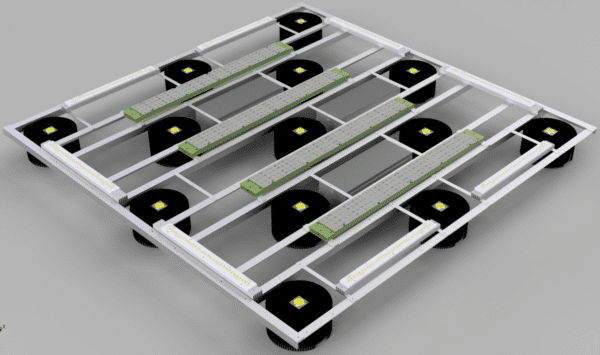

Figure 1: CAD model for our fixed-frame COB LED lighting array.

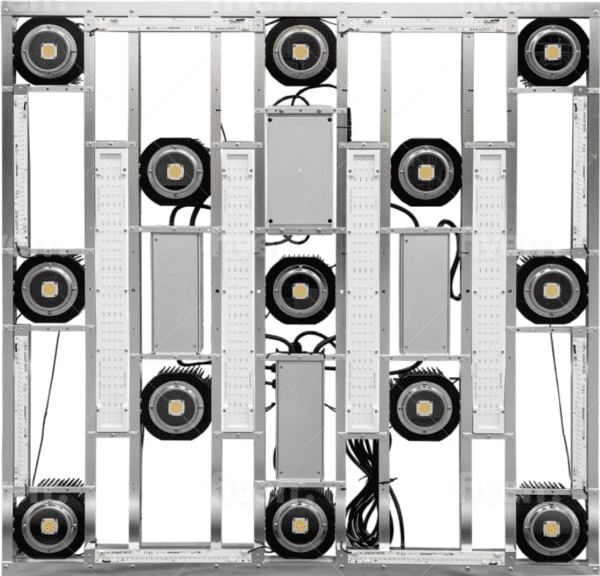

Functional Prototypes

This patented, fixed-frame lighting array is comprised of (13x) Samsung COBs, (8x) perimeter Samsung strips, and (4x) centralized color-surface mount device (SMD) custom LED modules made by our friends at KingBrite optoelectronics.

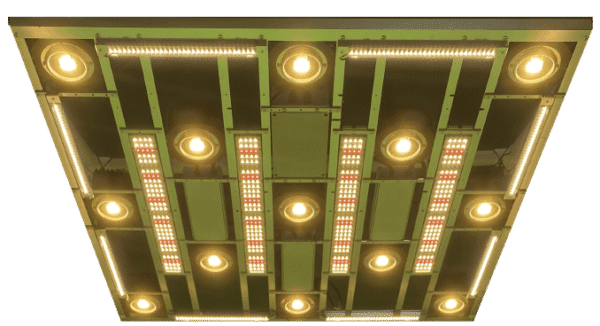

Figure 2: Commercial-Grade Functional Prototypes. Right: Lights on. Left: Lights off.

Mini Mode

In the left-hand picture it can be seen that a mode is activated where some of the lights are powered off. This is called mini mode! The purpose of mini mode is to give users a feature which they can use in the beginning growth phases when the plant canopy is taking up less surface area and requires less light intensity to flourish & thrive. Mini mode saves electricity costs, reduces HVAC requirements, and increases the product's lifespan.

Figure 3: Right: Perspective view of prototype. Left: Mini Mode!

Advanced Electronic Manufacturing

Our manufacturing partner is headquartered just 30 minutes from where Luminous Photonics was founded, in sunny South Florida! This means we have a real relationship with them and have built a solid working relationship to produce our patented lighting systems with people we actually know. AEM takes great pride in delivering stellar products, which shines through in the prototypes they've delivered thus far.

Having a manufacturing partner we can trust means we are poised to commercialize this product-line. Luminous Photonics is excited to take this project to the next level!